Casting occupies a large proportion of mechanical products. For example, the weight of castings for tractors is about 50-70% of the weight of the whole machine. There are 40-70% castings in agricultural machinery, and 70-90% in machine tools and internal combustion engines.

Among all kinds of castings, mechanical castings have the most varieties, the most complex shapes, and the largest amount, accounting for about 60% of the total casting output.

Therefore the casting for automatic hydraulic compressor moulding machine also occupies a large percentage.

In all castings, the unprocessed surface and appearance quality of castings have a considerable impact on the commercial properties of castings, which are expressed in the following five points:

1. Surface unevenness (box expansion, shrinkage and sand inclusion);

2. Surface or inner cavity cleanliness (sticky sand, sticky "paint layer");

3. Flatness deviation (unworked surface is undulating and uneven);

4. Surface roughness;

5. Contour definition

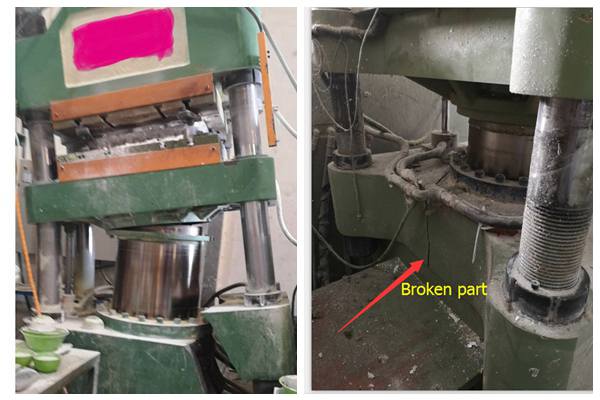

When the quality of the castings of melamine tableware compression machine is not well controlled, the following risks will occur.

1: There will be a rupture of the cylinder

2: The upper and lower covers will break

3: The tension column will break

It will be worse that all broken problems of the melamine crockery molding machine will directly cause the machine to stop and fail to work. It always takes a long time to get the new castings from China, and ordinary workers would not able to replace it, which directly hindered the normal production process.

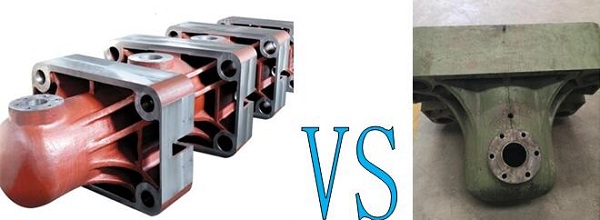

Comparison of Guide Pillar by Shunhao & Other Company

Comparison of Cylinder by Shunhao & Other Company

Shunhao Factory solve this problem from the very beginning

The Advantages of castings produced by Shunhao

1. Advanced and precise CNC machine to ensure the quality of castings

2. Strictly implement the strict production process to ensure that each step is qualified

3. Experienced engineer team and professional QC inspection

P.S. Production Equipment & Quality Control Equipment

Production Equipment

- Two sets of 10 tons Electrical Induction Furnace

- One set of 6tons Electrical Induction Furnace

- One set of 1ton Electrical Induction Furnace

- 14 meters Computerized Heat Treatment Equipment

- Two sets of 6 meter x 2.5 meters Blasting Equipment

- 5 Production Lines of Furan Sand Molding

- 1 Production Line of Wet Sand Molding

Quality Control

- Vacuum Emission Spectrometer(Switzerland)

- Computerized Universal Testing Machine(Taiwan)

- Metallurgical Microscope(Japan)

- Portable Metallurgical tester

- C.E.Meter

- Hardness Tester

- Portable Hardness Tester

评论

发表评论